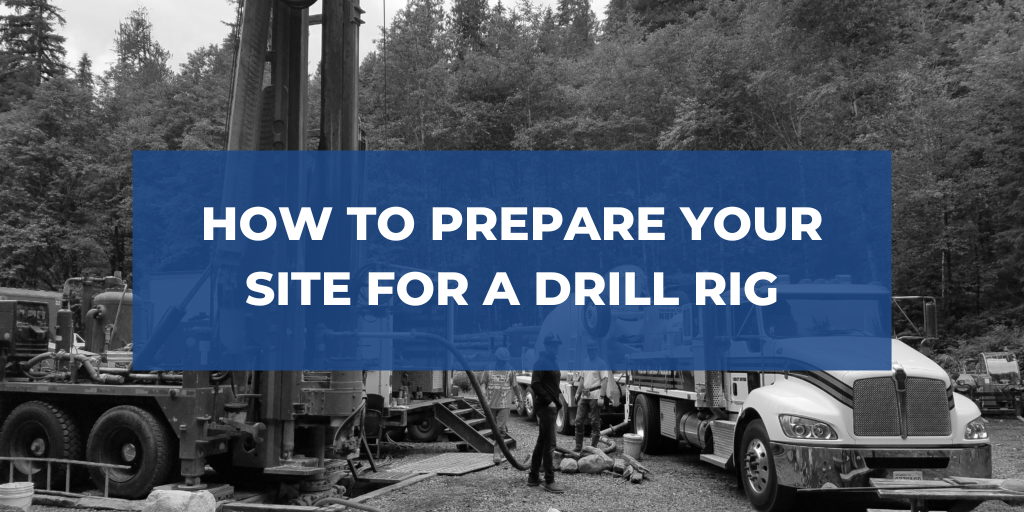

Two of the most common questions customers ask us is how big our drill rig is and whether or not their site will be able to accommodate it. These are important questions as our access to a worksite directly impacts our ability to drill your well.

While every site requires different drill rigs and supporting equipment, this blog will answer questions about how to prepare your worksite for our most common setup and drill rig.

The DR-24 Drill Rig

At TPD, our wide-ranging fleet of drill rigs ensures we get the job done. However, it is our Foremost DR-24 that is most likely to be at your worksite.

DR stands for Dual Rotary and 24 means it sets casing up to 24” in diameter. The enormous rig is approximately 43 feet long, with a drill tower that telescopes up to 60 feet high.

As you can imagine, this piece of equipment alone requires plenty of space to get in and out of the site as well as space above to raise the drill. Common upward obstructions include tree branches, power lines, and light poles.

Because of the size of the drill rig as well as the need for other equipment on-site, we often coach our clients to prepare their worksite with the following basic layout.

Basic Worksite Layout

Every worksite we encounter is unique. Obstacles are anything from inclines in the land to tree branches above and barriers to access. This site layout will help you determine if your site is ready to accommodate our drill rigs.

Access

The most important thing to remember on any job site is access. Access means more than just our ability to get the DR-24 in and out of your driveway. It means we can set up our entire rig and support equipment and still get in, out, and around the setup with other necessary vehicles such as forklifts.

Space for the Drill Rig and Tools

Once you’ve determined your drill site, it’s helpful to note that we’ll need an additional 45 feet (minimum) in front of that site and 30 feet behind it.

The drill rig backs up to the drill site and will take up the 45 feet in front of it. Behind the site is the tool laydown area. We use this space to lay out our drill rods, bits, stabilizers, and other materials that we need to access throughout the project.

Area for Support Vehicles

With our basic site layout, we need at least 4 feet on either side of the drill rig in order to accommodate the support truck. This truck sits alongside the tool laydown area. It stores all of the tools we need for drilling as well as the water used to drill your well.

For longer, more complex drilling projects, we also require an additional staging area for a second support truck. This second truck houses additional tools as well as space for the crew to grab a coffee.

Cuttings Discharge Area

The final thing to consider in a basic drill site layout is the area where the cuttings will discharge. The drill cuttings discharge at about 60 degrees on the opposite side as the support vehicle. If you don’t require us to collect the cuttings, then the discharge space is approximately 60 feet long and 15 feet wide.

If you choose to have us contain and remove the cuttings, then we use an additional 8 feet on the discharge side of the site (as well as room to place and remove the containers with a forklift).

Working with Tacoma Pump and Drilling

It’s our goal to make working with TPD easy, smooth, and enjoyable. If you have any questions about your worksite and whether or not it will accommodate our drill rigs, feel free to contact us directly. We’ve been drilling in the Pacific Northwest for nearly nine decades and would love to help make your drilling experience the best it can be.